Description

Model: CL44ENVL

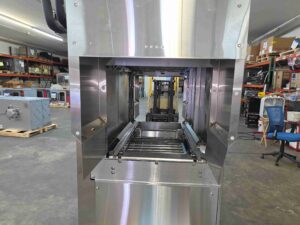

Hobart Single Tank High Temperature Conveyor Dish Machine

New – Factory Show Item

Hobart Details CL44ENVL

- 202 racks per hour

- Opti-RinSe™ system

- Rapid return conveyor drive mechanism

- Insulated hinged double doors with door interlock switches

- 19.5 inch chamber height opening

- Top mounted micro-processer control module

- Energy saver mode

- Dirty water indicator

- Manager activated low temperature alert

- NSF rated configurable Pot and Pan dwell mode

- Configurable “intelligent” smart delime alert, determined by water hardness test at installation

- Service diagnostics

- NAFEM Data Protocol compliant

- Computational fluid dynamic designed selfaligning wash manifolds

- Stainless steel debossed anti-clogging wash arms

- Removable integrated pump intake screen

- Stainless steel self-draining pump and impeller

- Single, sloping scrap screen and deep basket

- Stainless panels enclose perimeter and bottom

- Door actuated drain closure

- Convertible hot water or low temp final rinse

- Vent fan and booster heater control

Dimensions & Utilities

- 63.5 in. W x 31-1/16 in. D x 68.5 in. H

- 480V / 3-ph, 23.6 amp

Power Type: 480V 3-phase power required

Dealers Pricing: $40,612.00

Free Shipping with lift gate service to continental united states businesses – Please be aware the product will ship by freight carrier in a full size tractor trailer and will need room to get in and out or to turn around.

CL44ENVL Conveyor Dishwasher Information

Well equipped with high-tech features for convenience and performance, this Hobart CL44EN-BAS8 single tank high temperature conveyor dish machine is the efficient unit that won’t only simplify your warewashing process, but drastically reduce energy usage and its associated costs. Operating from left to right, the unit accommodates 202 racks per hour, using an impressively conservative 0.62 gallons per rack. The Opti-RinSe system works to minimize the rinse water used, as well as the energy used to heat the water, successfully reducing both by 50%. A unique spray pattern promotes such efficiency.

Operation of the unit is made easy by the micro-processor control panel located on the front, top of the machine. This panel features an assortment of convenient modes, indicators, and alerts designed to help you understand, operate, and maintain the unit. For instance, an energy saver mode is built-in, as well as a pot and pan dwell mode. A dirty water indicator light illuminates when activated, and a low temperature alert can be activated by the manager to help monitor the sanitizing process. Plus, the integrated smart delime alert notifies the operator when the unit should be delimed. It bases the timing of the alerts on the water hardness level that’s programmed during installation.

Thanks to the large chamber height opening, the machine accommodates wares up to 19 1/2″ tall. These wares move along the conveyor, which features Rapid Return technology to move the racks through the machine smoothly. During the wash, the self-aligning wash manifolds and anti-clogging nozzles spray down the dirty items and the waste management system collects food particles. Thanks to the screen design and lift-out scrap basket, cleaning out the debris is fast and easy. The self-draining pump is even protected by a removable screen so that food particles can’t penetrate and cause malfunction.

This particular model boasts a built-in stainless steel booster heater. It’s a pressureless, 30 kW unit that is completely integrated with the rest of the machine. It allows the operator to use one switch to control both the dish machine and the booster heater.

For proper heat retention, the dish machine includes thermal layer curtains and insulated inspection doors. Plus, stainless steel panels surround the wash system, ensuring prolonged durability. The machine can be converted to low temperature operation in the field if desired. When used as a high temperature machine, it requires a 208V 3 phase electrical connection.

Overall Dimensions:

Width: 57 3/4″

Depth: 31 1/4″

Height: 79 9/16″

Capacity: 23 gallons

Packaging Equipment

L&D Appliance will package the items you purchase for free. This will be strapping the item to a wooden pallet, installing cardboard or cardboard corners and shrink wrapping the product.

Warranty of Products

All Vulcan and Wolf equipment are purchased as-is-where-is and do not carry the factory warranty. L&D Appliance does offer a 10-day warranty after the product has been installed. The installation needs to be by a professional that can set-up and install the equipment properly. Installation receipt and date will need to be provided for installed equipment for L&D Appliance to honor the 10-day warranty. Parts will be provided by L&D Appliance along with your local tech support for repairs.

Returns

Buyer has 15-days to return an item if they are not satisfied or purchased accidentally, the buyer is responsible for crating and shipping the equipment back to our warehouse in SC. Once the equipment has been inspected, L&D Appliance will process a refund less any damage, missing component cost, initial shipping cost (actual cost of original shipment even on free shipping promotion) and a 15% restock fee.

Delivery Inspection Required

Insure to inspect delivery for any significant damage caused by the freight carriers. If any major damage, please contact Alan 828-527-2241 before driver leaves. If severe damage, refuse delivery. If slight damage, insure driver notes damage before leaving. The is critical, because without documentation the freight company will not accept a claim for the damage and the item delivered will now be the responsibility of the recipient for repairs.